For decades, fleet maintenance was either reactive or preventive. Something broke, and you fixed it, or you scheduled routine service across your vehicles, hoping to prevent issues before they started. Both approaches have limits, leading fleets to move to a third, smarter model: Predictive Maintenance.

Reactive maintenance means waiting until a battery dies or a sensor fails before taking action, leading to unplanned downtime and unexpected costs. Preventive maintenance can reduce those surprises, but it often applies one-size-fits-all service intervals to assets with very different usage patterns. That adds cost without always delivering value.

Rather than responding to failure or working from fixed schedules, predictive maintenance uses real-time data to flag issues early. It helps you intervene before a part fails, based on how and where that vehicle is operating. The result is less downtime, lower spend, and more confident planning across the board.

Reactive vs. Predictive: What’s the Difference?

Reactive maintenance is exactly what it sounds like. A problem happens, and your team scrambles to fix it. You’re already behind.

Preventive maintenance takes a more proactive approach, but it still relies on general timelines, not actual wear or conditions. You might service a battery that’s still healthy or miss signs of trouble on a truck that’s outside the normal cycle.

Predictive maintenance flips the script by using data like voltage trends, idle cycles, or cab temperature. It flags issues as they emerge, allowing your team to respond based on risk, not routine. It’s smarter, more targeted, and scalable across even the most complex fleets.

Why It Matters Now

This shift isn’t theoretical. It’s happening because the pressures on fleet operations are increasing, and traditional approaches can’t keep up.

- Labor is tight. Techs are hard to find and harder to keep. Predictive maintenance helps your existing teams prioritize the work that matters most, rather than constantly playing catch-up.

- Budgets are shrinking. With rising parts and labor costs, there’s less room for trial and error. Predictive insights help reduce emergency repairs and let you plan for shop time and inventory needs.

- Downtime is costly. Whether you’re moving retail goods or industrial equipment, missed deliveries impact customer relationships. Predictive models minimize unplanned service and help protect your schedule.

- Fleets are more complex. You’re not just managing a few identical trucks anymore. You’ve got assets across climates, regions, and use cases. Predictive tools let you service each vehicle based on actual conditions, not assumptions.

How the Smartportal and SmartInsights Make It Actionable

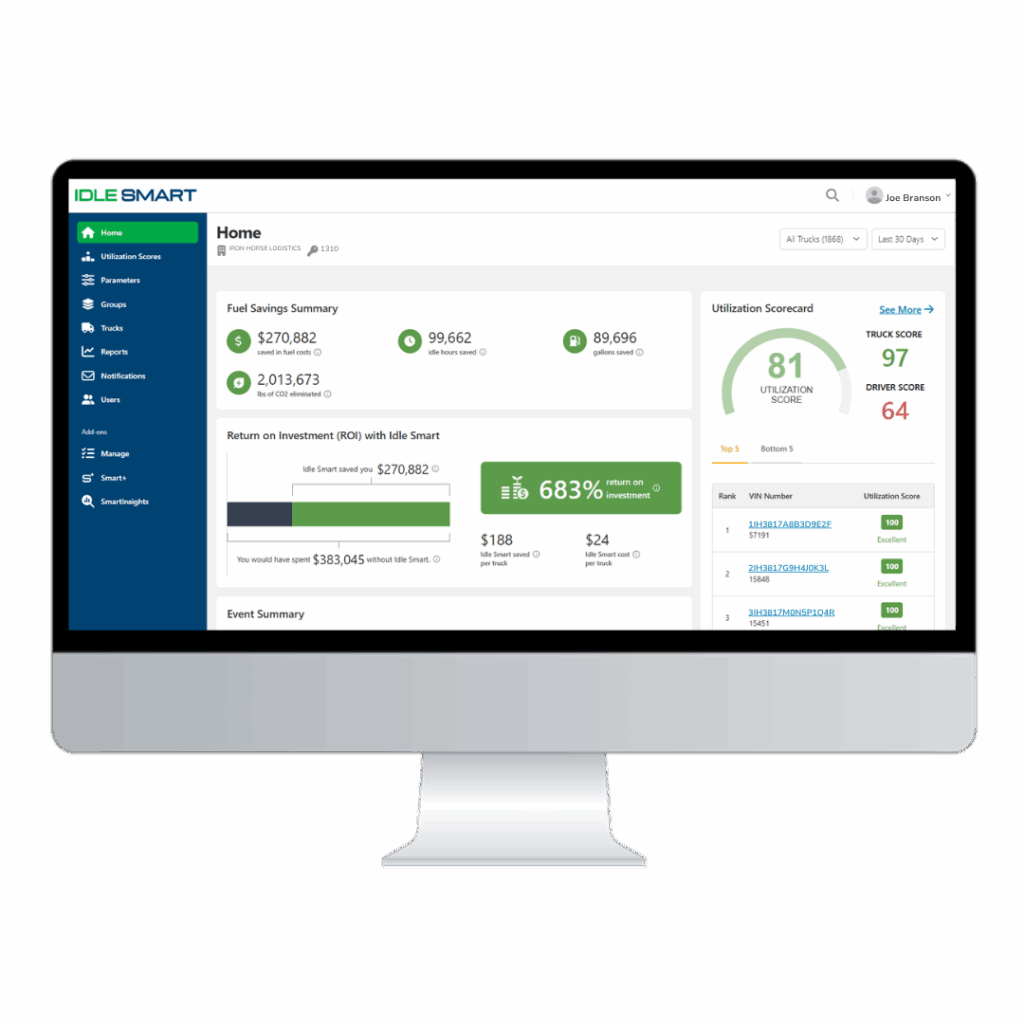

Idle Smart is purpose-built for enterprise-scale insight. Every subscription includes access to the SmartPortal and SmartInsights, our predictive maintenance tool that turns idle reduction data into real-world maintenance intelligence. That includes:

- Battery health analysis: Track voltage trends and spot early signs of battery decline before failure happens.

- Understand engine cycling: See how often and under what conditions Idle Smart is engaging, fleet-wide or by vehicle.

- Idle behavior insights: Detect unnecessary cycling tied to drivers or environments, so you can address usage and optimize performance.

These insights are accessible via the Smartportal and supported by a dedicated Customer Success Manager who helps translate insights into action, so your team gets clear, vehicle-specific guidance that aligns with your strategy.

Predictability Pays Off

One of the biggest values of predictive maintenance is the ability to plan, rather than react. When you can forecast potential failures, you can:

- Schedule repairs during natural downtime

- Avoid premium pricing on last-minute parts and labor

- Reduce emergency service calls and out-of-route repairs

- Keep vehicles and drivers on schedule

Predictability reduces friction for everyone, from shop teams to the executive suite. A maintenance lead might see fewer disruptions, an operations director might find opportunities to rebalance workloads, and a COO can gain confidence in uptime forecasts and SLA delivery.

Maintenance as a Strategic Lever

Historically, maintenance was treated as a cost center, but with the right data and tools, maintenance can directly support your fleet’s broader business goals:

- Extend asset life by timing repairs based on actual wear

- Reduce inventory waste through smarter part planning

- Improve sustainability by reducing avoidable idling

- Support driver retention by minimizing service-related delays

When your vehicles are operating in different regions, climates, and duty cycles, real-time visibility helps ensure that no truck gets under- or over-serviced.

Where Idle Smart Fits In

Idle Smart is a powerful piece of your maintenance toolkit, guiding your maintenance teams to the most critical repairs.

Your team gets ahead of potential failures, your assets stay healthier longer, and your operation runs with less risk. Because everything is centralized through the Smartportal, you can monitor trends across hundreds or thousands of vehicles in a single view, while still drilling down to the details that matter.

It Doesn’t Have to Be Complicated

We know “predictive maintenance” can sound technical, especially if you’re already juggling multiple platforms and priorities. That’s why we keep it simple. Every Idle Smart subscription includes two SmartInsights reports per vehicle, plus hands-on support from your Customer Success Manager. You don’t need a data science team to make this work.

You need the right information, at the right time, in a format that makes sense. That’s what we deliver.

Let’s talk about how Idle Smart + SmartInsights can support your maintenance strategy and help your fleet move with greater control and confidence.